A4CSEL for

Dam

Naruse Dam-

“Transforming the construction site into a factory” by A4CSEL

We have successively applied A4CSEL to automate vibratory rollers, bulldozers, and dump trucks onsite at several dam construction sites. Starting in 2020,

the system is being applied to casting the CSG (cemented sand and gravel) embankment of the Naruse Dam (near Higashinaruse village, Akita Prefecture).

In this construction project, more than twenty automated construction machines (comprising five types) are scheduled

to operate continuously day and night for up to 70 hours in a row during the peak season.

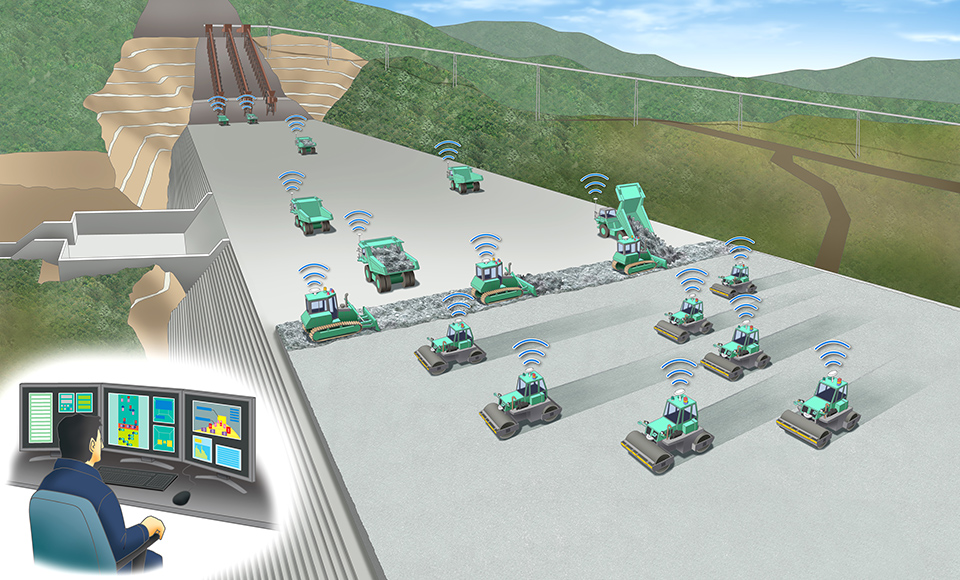

Illustration of A4CSEL in operation at Naruse Dam

Four “IT pilots” control more than twenty automated construction machines

In the control room of Naruse Dam, four “IT pilots” control more than twenty automated construction machines. By transmitting work data created according to an optimized plan, it is possible to control multiple automated construction machines in unison so that they cast the CSG embankment. The IT pilots monitor the automated construction machinery in operation and prepare construction plans based on daily changing construction conditions.

At the dam embankment, multiple automatic dump trucks, automatic bulldozers, and automatic vibratory rollers are working in unison to unload, spread, and compact the embankment materials (CSG) and then cast the CSG embankment. The automated construction machines work day and night, except during refueling time, and during the peak construction season, 70 hours of continuous construction are scheduled. Moreover, nobody can enter the automated construction area, so accidents involving contact between people and construction machinery are eliminated, thereby improving site safety.

The control room of Naruse Dam operated by IT pilots

A4CSEL’s automated construction machinery working in collaboration to place CSG to the dam embankment

Automated construction machinery

Automated dump truck

Automated bulldozer

Automated vibrating roller

Automated sweeper

Japan’s largest trapezoidal CSG dam—which can only be built by A4CSEL

Naruse Dam is Japan’s largest trapezoidal CSG dam with an embankment volume of 4.85 million m3. Due to heavy snowfall in the region, the embankment cannot be cast during the winter. During the peak season, the construction must progress at a rate of 250,000 to 300,000 m3 of embankment per month, which is more than twice the rate of similar projects to date. CSG casting of the embankment by applying A4CSEL started in May 2020 and has completed a second season. In 2021, the ratio of automation for the embankment casting exceeded 94%, and we are striving for even faster construction during the 2022 season.

Automated bulldozer waiting while dump truck unloads CSG

Unmanned automated construction machinery constructs the dam with maximum efficiency

ColumnKAJIMA DX LABO

Enjoy it in real life or online!

Located on the right bank of the construction site of Naruse Dam, KAJIMA DX LABO introduces Kajima’s vision of the future of civil engineering, A4CSEL, and construction of Naruse Dam through dioramas and panel AR (augmented reality). Visitors can learn through experience via a tablet. Standing on the deck overlooking the construction site, visitors can point the tablet towards the embankment under construction and see the completed structure in AR. A4CSEL’s control room is located on the floor above the KAJIMA DX LABO.

External view of KAJIMA DX LABO

AR appears when the tablet is held over the diorama

An “Online Museum” is also available and allows visitors from all over the world to enjoy the KAJIMA DX LABO regardless of the limited number of visitors due to the COVID-19 pandemic. You can choose between Japanese or English as your language, and you can freely explore the lab from your smartphone, PC, or tablet, as well as watch videos shown in the theater.

Entrance to the Online Museum

Example display in the Online Museum