A4CSEL for

Tunnel

Successful construction of a mountain tunnel in six automated

and remotely controlled steps by A4CSEL for Tunnels.

“A4CSEL for Tunnels” aims to improve the safety, productivity, and quality of construction of mountain tunnels.

Automated and remote excavation operations in mountain tunneling have made it possible

to carry out highly dangerous work around the face unmanned and efficiently.

Development began in the mockup tunnel opened in 2018, establishing the fundamental technologies required for automated and remote construction.

From 2021, the developed technology had been demonstrated in the Kamioka Test tunnel under the same environment and conditions as the actual construction.

In 2024, all six steps were automated and remote-controlled. “A4CSEL for Tunnels” was completed.

Kajima’s concept of “A4CSEL for Tunnel”

Automation and Remote Control of Six Steps in Mountain Tunnel Construction

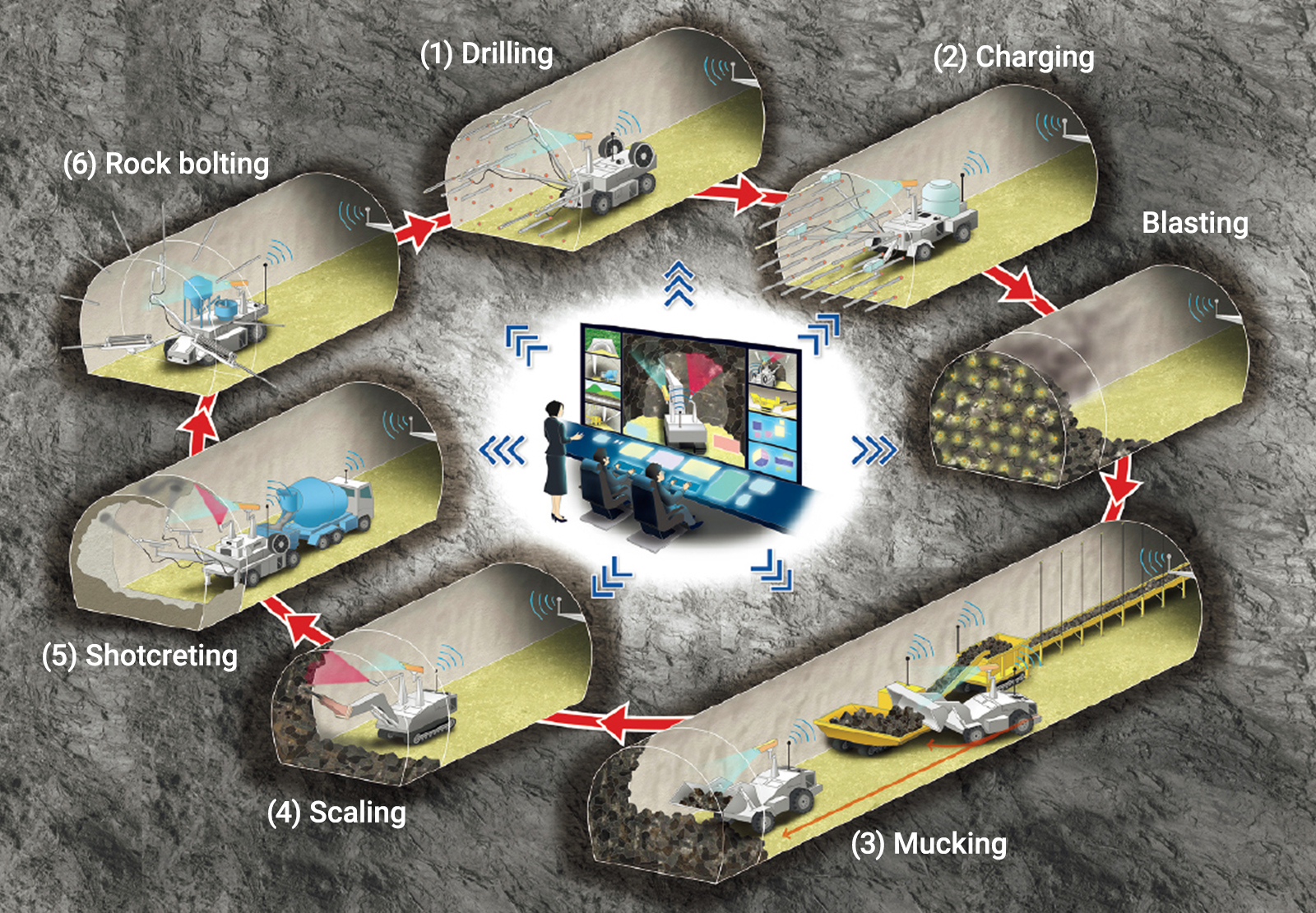

By automating and remote-controlling six steps of excavation work in mountain tunneling, we have dramatically improved the safety of the face and achieved significant labor savings.

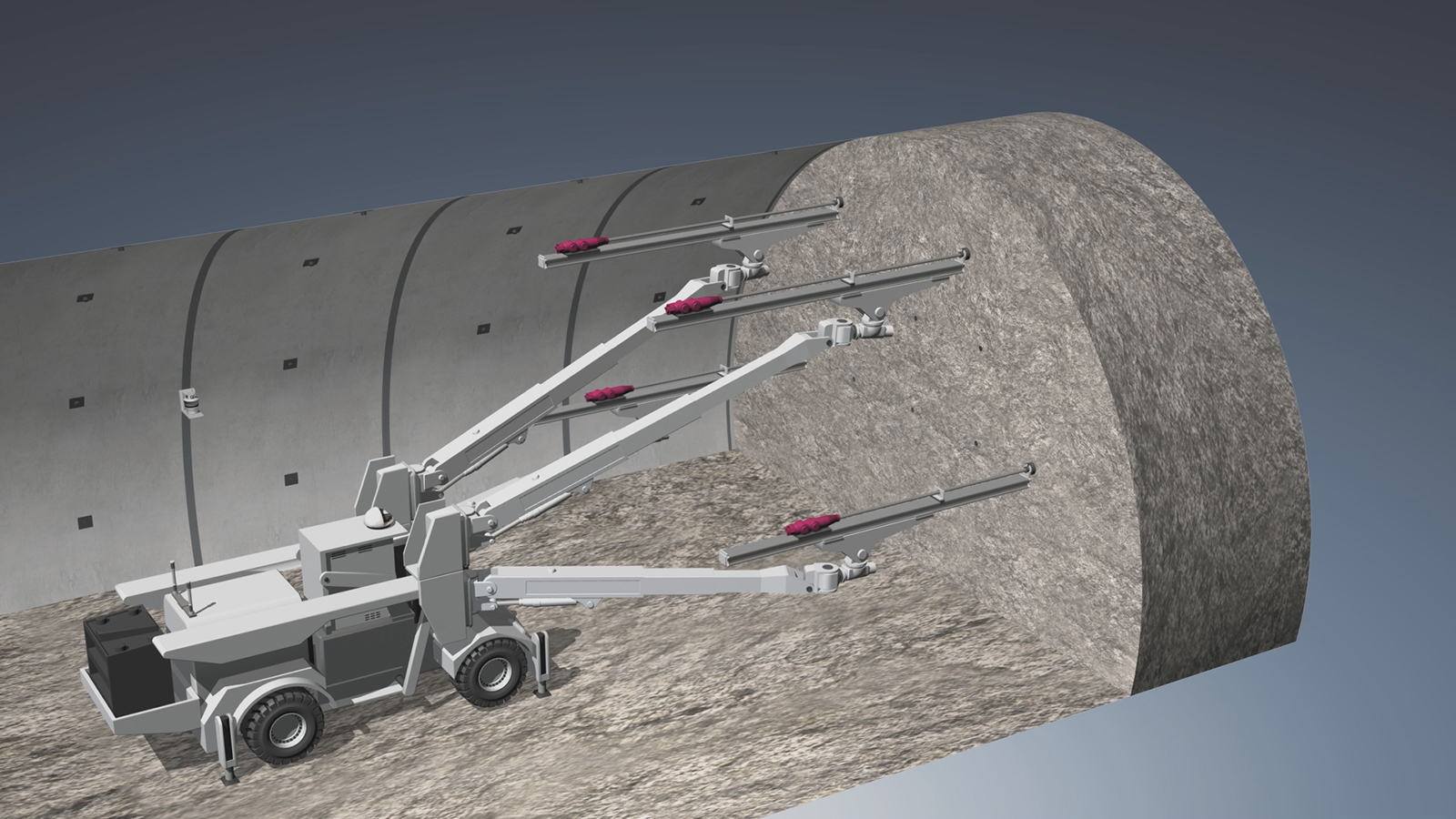

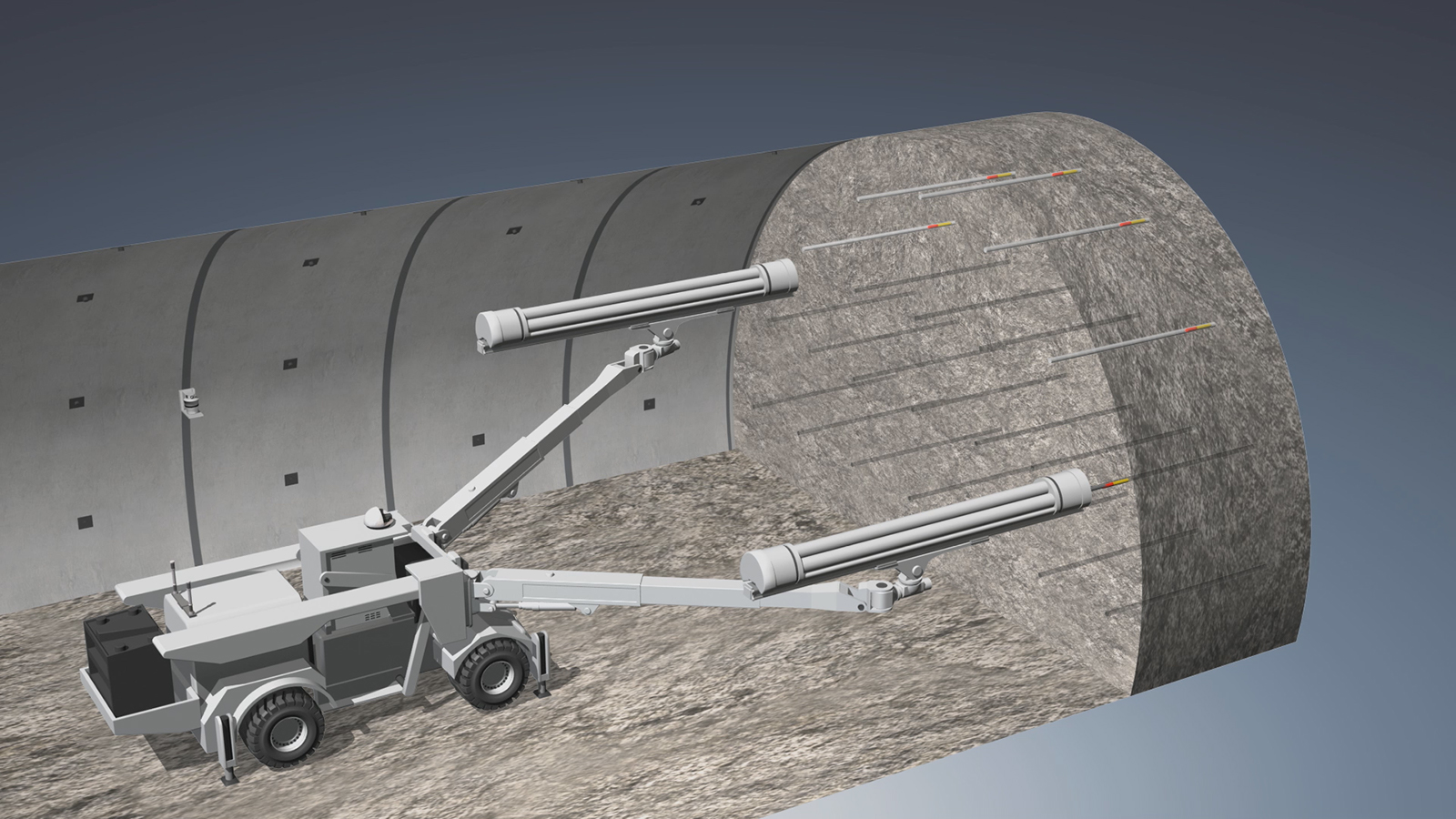

A4CSEL for Tunnel

Computer-graphic illustration of automation of the six tunnel construction steps

STEP1Drilling

An “optimal automatic blasting-design system”—which automatically generates optimal blasting patterns from rock hardness and softness data acquired during drilling by a computer-controlled drill jumbo— was developed. Based on this blasting-design system, the computer-controlled drill jumbo performs the drilling operation automatically. As the number of holes and the volume of explosives are optimized, the amount of overbreak is reduced by 60% and the cycle time by 20% compared to the manual operations.

STEP2Charging

For the automation of loading, in-situ manufactured explosives, which are non-explosive in the loading machine from a safety point of view and only become explosive when the raw materials are mixed together in the borehole, are suitable. As a first step toward the automation of charging, we have conducted the first full-section blasting of a mountain tunnel in Japan using “bulk-emulsion” explosives manufactured in-situ.

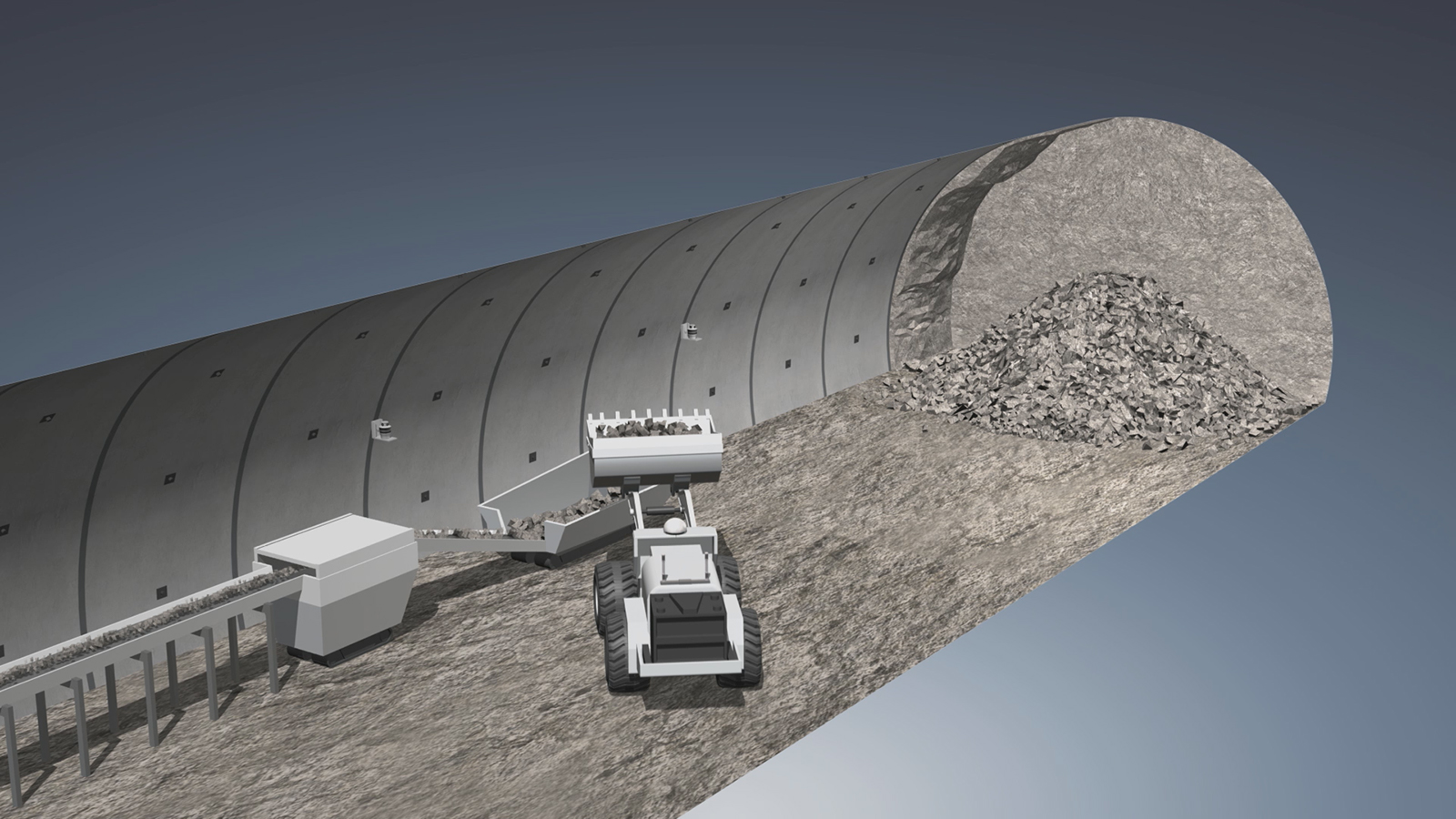

STEP3Mucking

By creating a map of the tunnel based on measurement data from a LiDAR device installed on the wheel loader and utilizing SLAM technology to estimate the loader’s position in real time, it is possible to automate the loading, transportation, and unloading of excavated debris even inside tunnels on non-GNSS environments. By combining the wheel loader with a remotely-controlled backhoe, we have demonstrated complete unmanned operation in the vicinity of the face during mucking operations.

STEP4Scaling

We developed an “Breaker-guidance system” that uses a 3D laser scanner mounted on the breaker body to measure the overbreak. The breaker can then be operated remotely to that position, making it possible to completely unmanned the face during the overbreak removal.

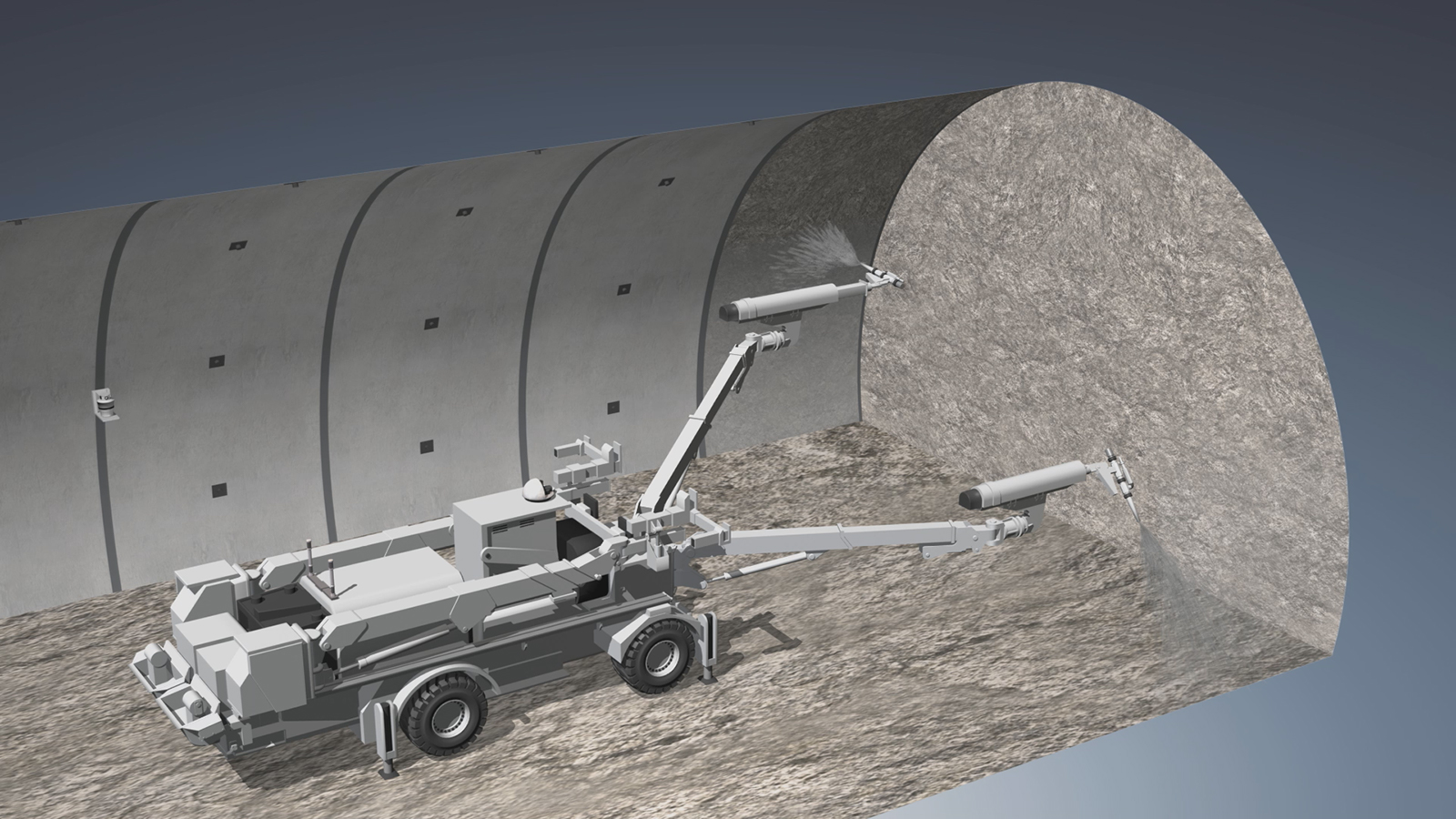

STEP5Shotcreting

We developed an “automatic shotcreting system” for automatically generating a shotcreting plan based on measurements of the rock surface obtained by 3D laser scanner and program-controlling two nozzles on the left and right sides of the shotcreting machine. The tunnel support is carried out using a “erection guidance system” that remotely controls the erector according to the calculated position of the attached target. As a result, it is possible for a single operator to carry out shotcreting and erection from the driver’s seat and without having to enter the area near the work face.

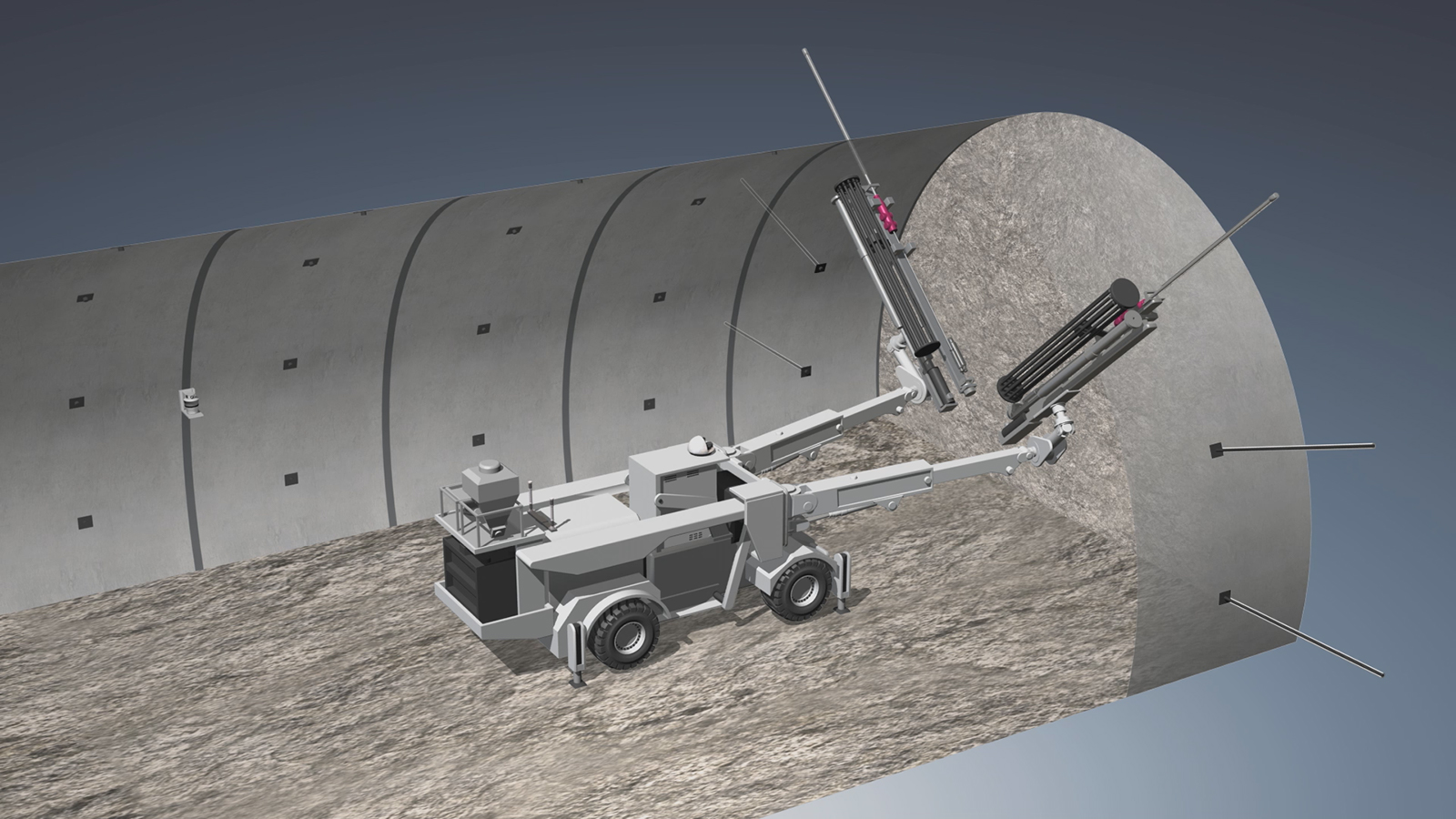

STEP6Rock bolting

We developed a “two-boom rock-bolting machine” that automates the rock-bolting process (i.e., placing rock bolts radially into the tunnel). Following the three-step sequence of rock bolting (drilling, mortar injection, and rock-bolt insertion), the machine automatically places up to 20 rock bolts in succession by using its two booms on either side. We demonstrated that rock bolting by a single operator is feasible.