CO2-SUICOM

CO2-Storage and Utilization

for Infrastructure by

COncrete Materials

(POINT 01)

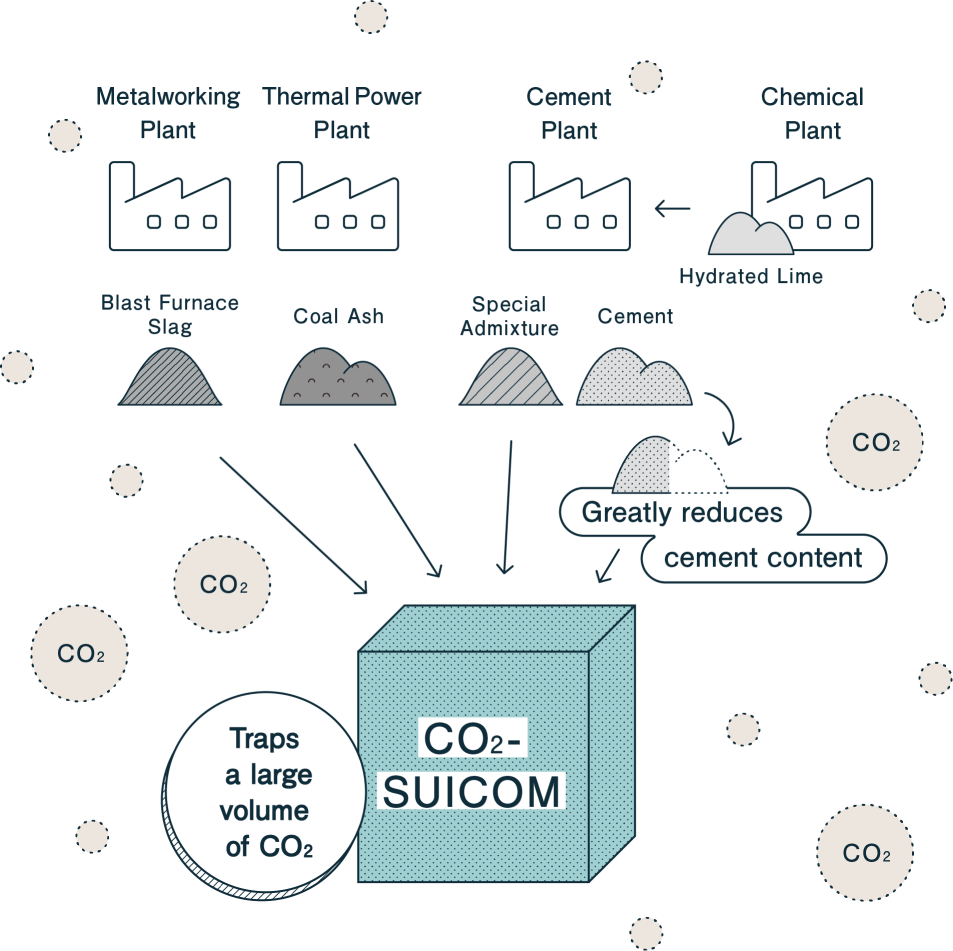

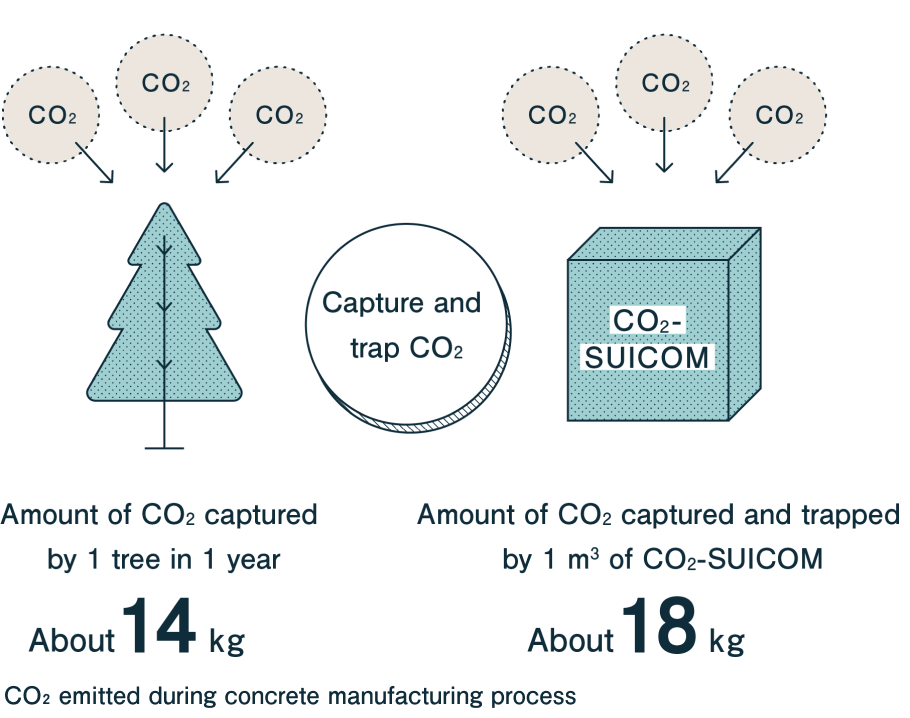

CO2-SUICOM—jointly developed by Kajima, The Chugoku Electric Power Co., Denka, and Landes Co.—is the world’s first carbon-capturing concrete. One of the main components of concrete is cement, a product of an emission-heavy manufacturing process. With CO2-SUICOM, over half the cement is replaced with a more environmentally friendly substitute, allowing us to greatly reduce the amount of CO2 produced from manufacturing the concrete. In fact, the substitute hardens by capturing CO2 in the air—like trees—essentially putting the total CO2 emissions from manufacturing the concrete at net-zero or less.

While we often talk of reducing CO2 emissions, the fact that making more CO2-SUICOM can actually lead to less CO2 in the air suggests there is another way: reusing CO2 emissions. Even the Japanese government has taken notice, introducing the product as the world’s first successful carbon-capturing concrete in its “Green Growth Strategy Through Achieving Carbon Neutrality in 2050.” Soon, the world will notice as well.

(POINT 02)

Generally, concrete hardens through a chemical reaction between cement and water. But with CO2-SUICOM, over half the cement is replaced with a material we call γ-C2S. Instead of reacting with water, γ-C2S reacts with the CO2 in the air to harden. After mixing the materials need to create CO2-SUICOM, the concrete can be placed in a location with high CO2 levels so it can capture the CO2 and harden, trapping the gas inside. For example, a thermal power plant or other facility that produces carbon-heavy exhaust gases can redirect the gases into a carbon sequestration chamber, where concrete products made with CO2-SUICOM can be placed to capture the CO2 in the gases.

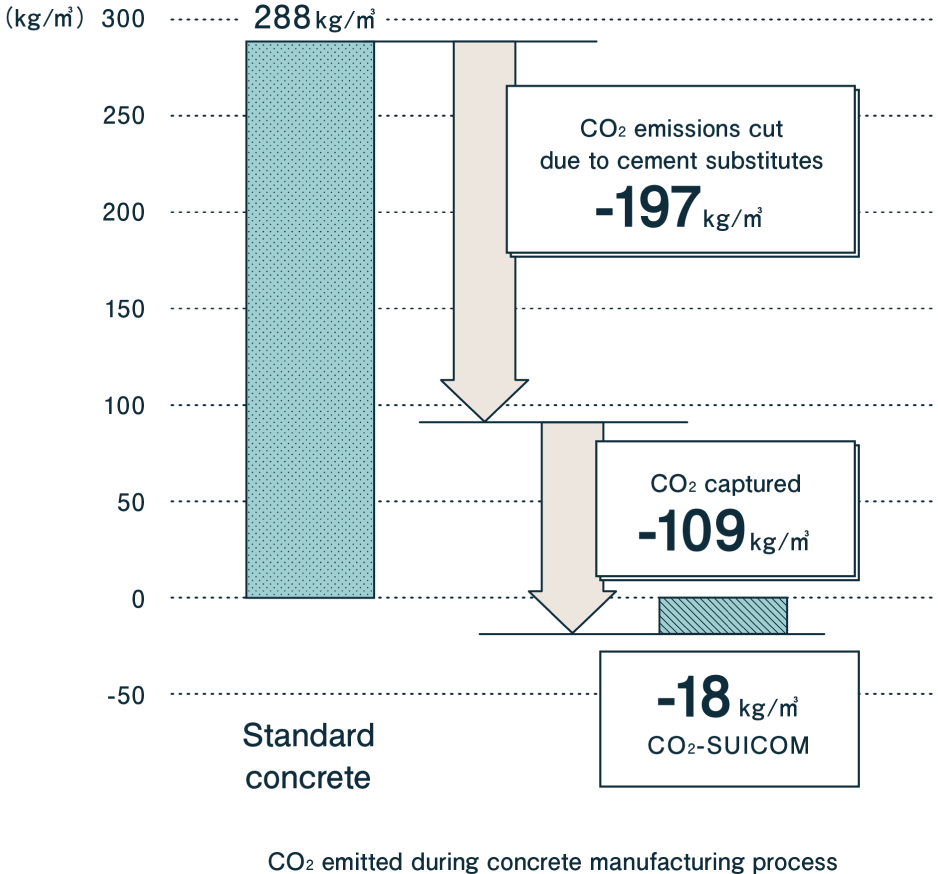

While the manufacturing process for standard concrete produces about 288 kg/m³, the figure is about 197 kg/m³ less for CO2-SUICOM, as over half of the cement is substituted with low-CO2 industrial byproducts and other materials. Also, the concrete itself can capture and trap about 109 kg/m³. This results in a total carbon emissions cut of about 306 kg/m³, or total emissions of -18 kg/m³—less than net-zero.

(POINT 03)

Japan uses an annual 91 million ㎥ of concrete. Replacing all this concrete with CO2-SUICOM will result in an annual cut of 27.84 million tons of CO2 emissions—about one-third the volume that can be captured by Japan’s forests every year. Of this amount, 1.64 million tons is due to the concrete being carbon negative—that is, capturing more CO2 already in the air or in exhaust gases than it emits.

(09)

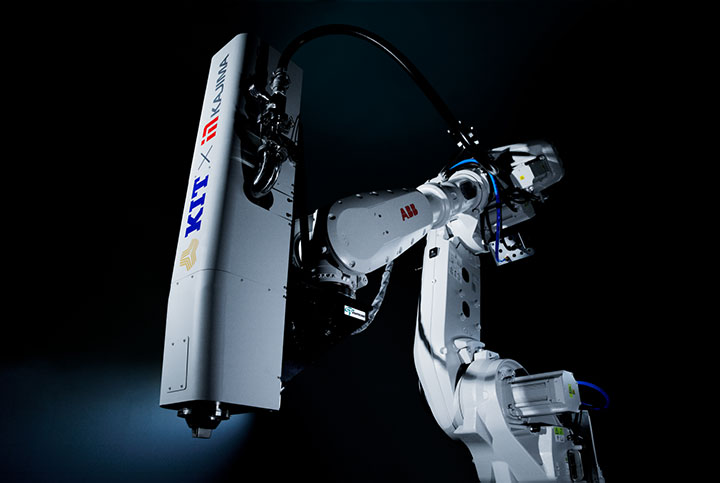

Stay-In-Place formwork made of CO2-SUICOM, a carbon-negative concrete that emits practically zero or less CO2 during concrete production, was applied for the first time to highway bridge pier construction. CO2-SUICOM is a concrete that can absorb and fix CO2 within its interior during the manufacturing process.

(06)

The Japanese construction industry is encountering serious problems, such as a lack of technicians and productivity issues caused by smaller workforces.

(03)

Together with Nippon Concrete Industries Co., we are developing carbon-negative concrete solutions that can greatly reduce the output of CO2.