What is A4CSEL?

Kajima aims to "transform the construction site into factory"

by automating general-purpose construction machinery and optimizing construction planning.

As a construction production system with automated operation of construction machinery at its core,

A4CSEL transmits work data based on optimized plans to general-purpose construction machinery that has been modified for automation in a manner

that allows the construction machinery itself to work autonomously and automatically.

It is the world’s first construction production system based

on the concept of simultaneously operating many automated construction machines with fewer operators.

A4CSEL:Automated / Autonomous / Advanced / Accelerated Construction system for Safety , Efficiency , and Liability

Initial development concept of A4CSEL

Solving problems facing the construction industry

and realizing the concept of “transforming the construction site into a factory.”

Features of A4CSEL

- Feature01

Improved productivity - Feature02

Improved safety

at the construction site - Feature03

Outstanding versatility

The construction industry is facing an urgent shortage of labor owing to mass retirement of skilled workers and a decrease in the number of young workers entering the workforce. In the meantime, it has been pointed out that productivity in the construction industry is lower than that in the manufacturing industry, and the reason for that discrepancy in productivity is that the old labor-intensive methods—which relied on the skills of workers—could not be changed because the structures to be built are “one-of-a-kind,” specifications vary from site to site, and the construction work is done outdoors. On top of that, still classed as a “hazardous industry,” the construction industry accounts for 32%* of fatal accidents across all industries.

Aiming to solve the pressing issues facing the construction industry today, namely, labor shortages, low labor productivity, and high occupational accident rates, Kajima has been striving to not simply “introducing ICT to individual tasks” but to “dramatically transform the production process.” Our goal is to “transform the construction site into a factory” like a manufacturing company.

*From the Ministry of Health, Labor and Welfare “Occupational Accident Statistics, Reiwa 2 (2020)”

Casting work on the embankment of Naruse Dam with multiple automated construction machines working in coordination

The keys to transforming the construction site into a factory are

“skilled automatic operation” and “optimal planning.”

The first step in ensuring that production is carried out as planned—that is, in the manner of a factory—is to analyze qualitative work methods that cannot be measured numerically, such as ones that rely on experience and intuition of workers, and restructure them as routine tasks in a way that reduces individual differences. In other words, each and every task that has been left to the skill of the operator must be detailed in a manual, and a machine must be made to perform the task by following a standardized procedure and using a standardized method. Aiming to implement automatic-operation technology that can match skilled operators and superior production-planning technology, which are the keys to meeting the above-described requirements, we are studying automatic construction machinary with the most-suitable operational capability for each job. In this study, we are utilizing AI methods and work simulations based on actual operational data collected from skilled operators. We are also investigating methods for planning combinations and arrangements of multiple machines—following optimum procedures—so that they operate in the most-efficient way.

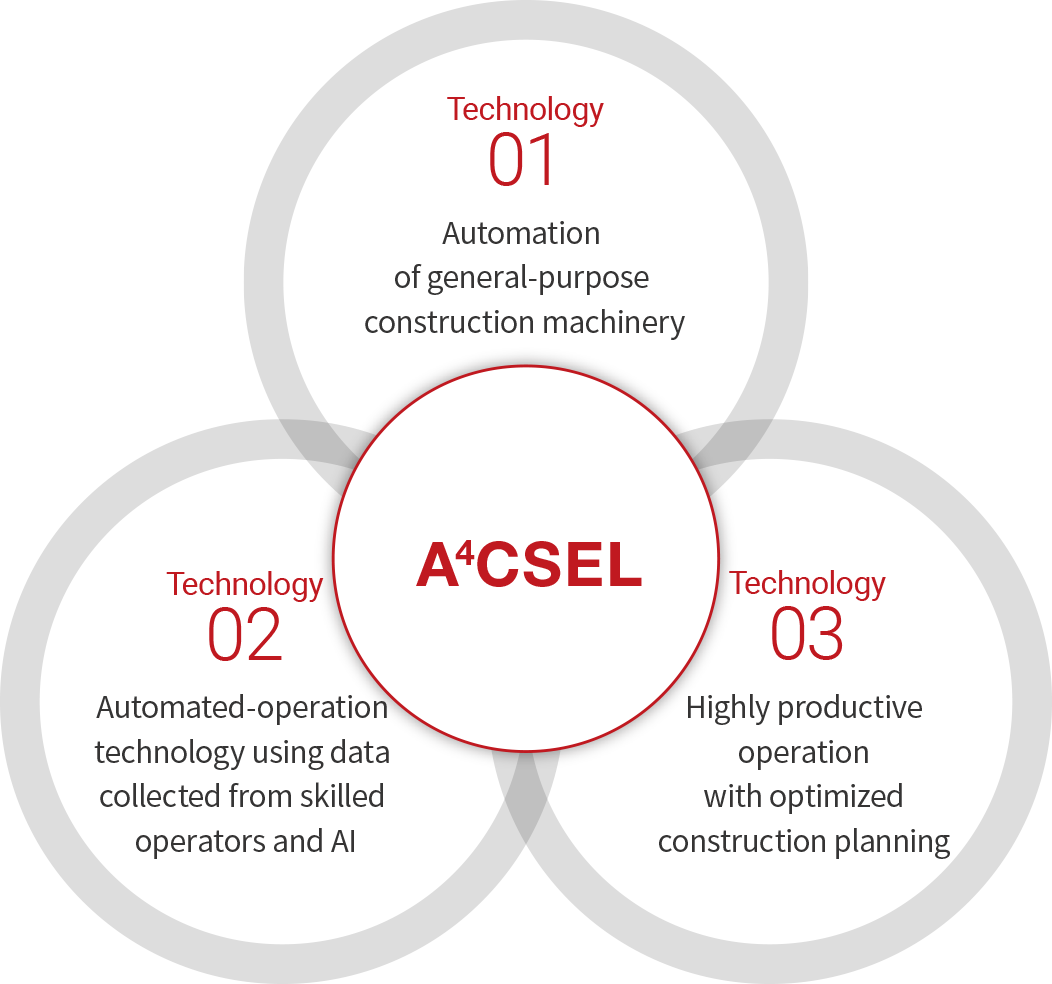

The three technologies that compose A4CSEL

A4CSEL consists of three technologies:

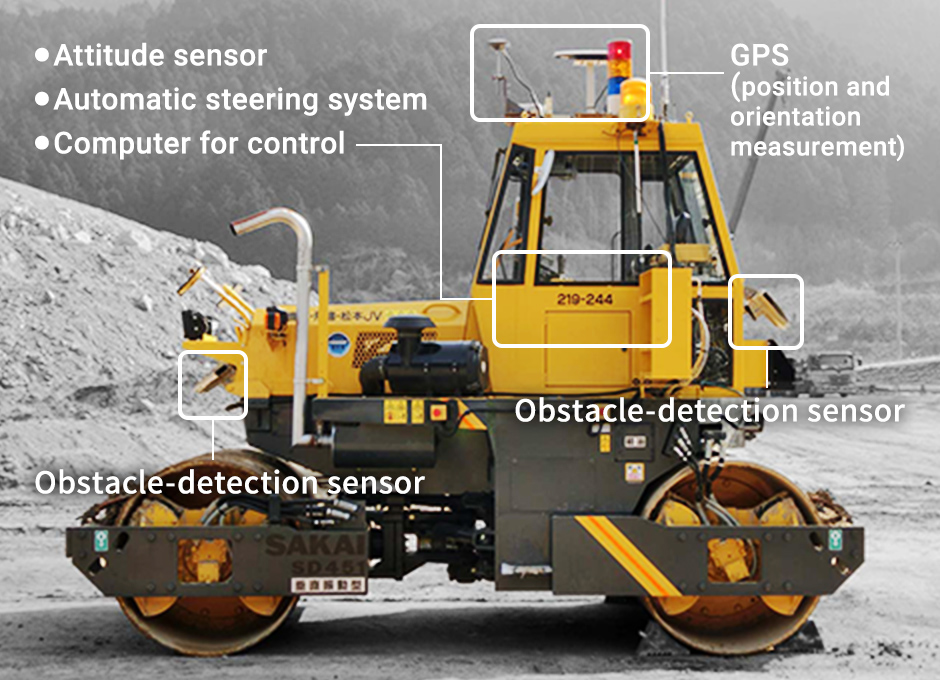

(1) technology for automating and remodeling general-purpose construction machinery;

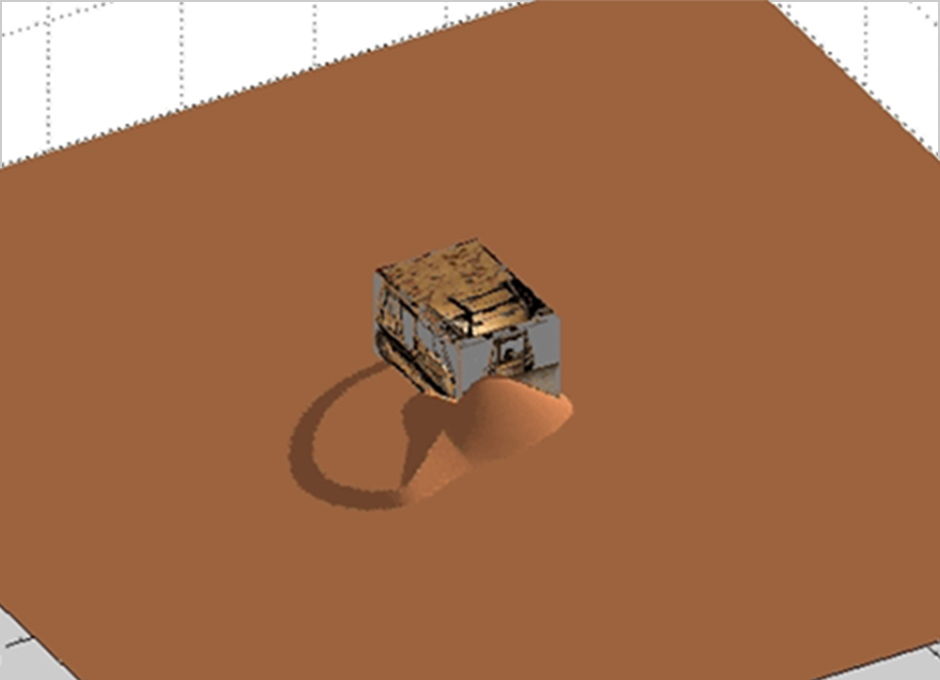

(2) automatic driving technology (considering work conditions and situations) incorporating AI methods based on the operation data gathered from skilled operators;

and

(3) construction-management technology that links a large number of machines so that they operate according to the most-productive construction plan.

A4CSEL enables (i) automatic creation of plans that optimize machine placement, work order, etc. and (ii) construction work to be performed autonomously and automatically in a manner in which all machines are working in harmony as if they were in a factory.(1) technology for automating and remodeling general-purpose construction machinery

General-purpose vibrating roller modified for automation

(2) automatic driving technology (considering work conditions and situations) incorporating AI methods based on the operation data gathered from skilled operators

Simulation of automatic operation under various working conditions (simulator of the spreading operation of a bulldozer)

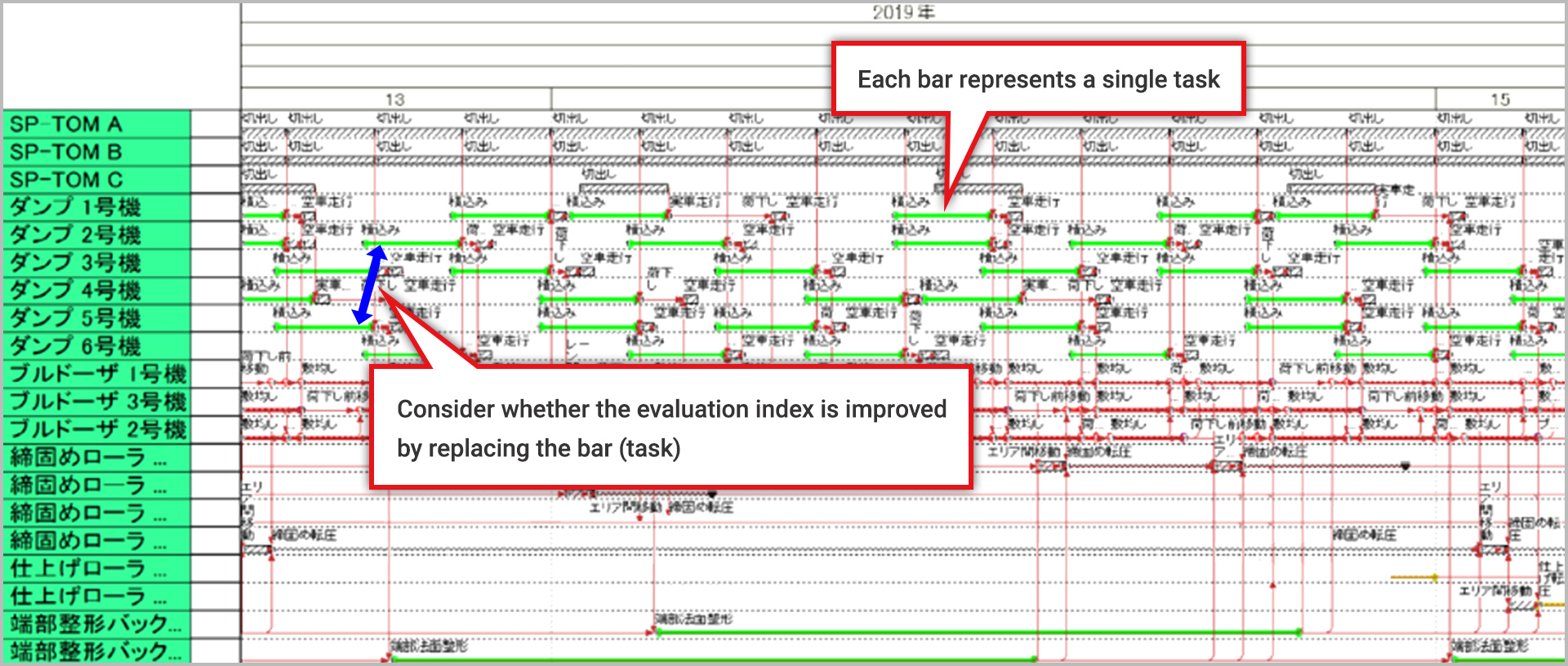

(3) construction-management technology that links a large number of machines so that they operate according to the most-productive construction plan

Illustration of optimization planning using AI methods

A4CSEL evolves while adapting to the ever-changing workplace

By reliably and continuously performing routine tasks, automated construction machinery enables production with consistent quality over a planned period of time. Moreover, productivity can be dramatically increased by controlling—with fewer people—multiple automated construction machines deployed at the site. It also improves safety because the risk of human-machine contact is greatly reduced. As a result, by linking these technologies to create optimal plans in response to the site environment and conditions, a factory that can respond to the ever-changing construction site can be created.

With a proven track record of success, Kajima has been applying this system, A4CSEL, to dam sites, at which a large amount of work involves construction machinery, so-called “heavy machinery earthwork.” We are following this application with automation in construction of mountain tunnels. We have also applied A4CSEL to post-disaster restoration work in places where people are unable to enter, and we have confirmed its effectiveness in such situations.

Illustration of a dam site realized "transforming a construction site into a factory" by A4CSEL

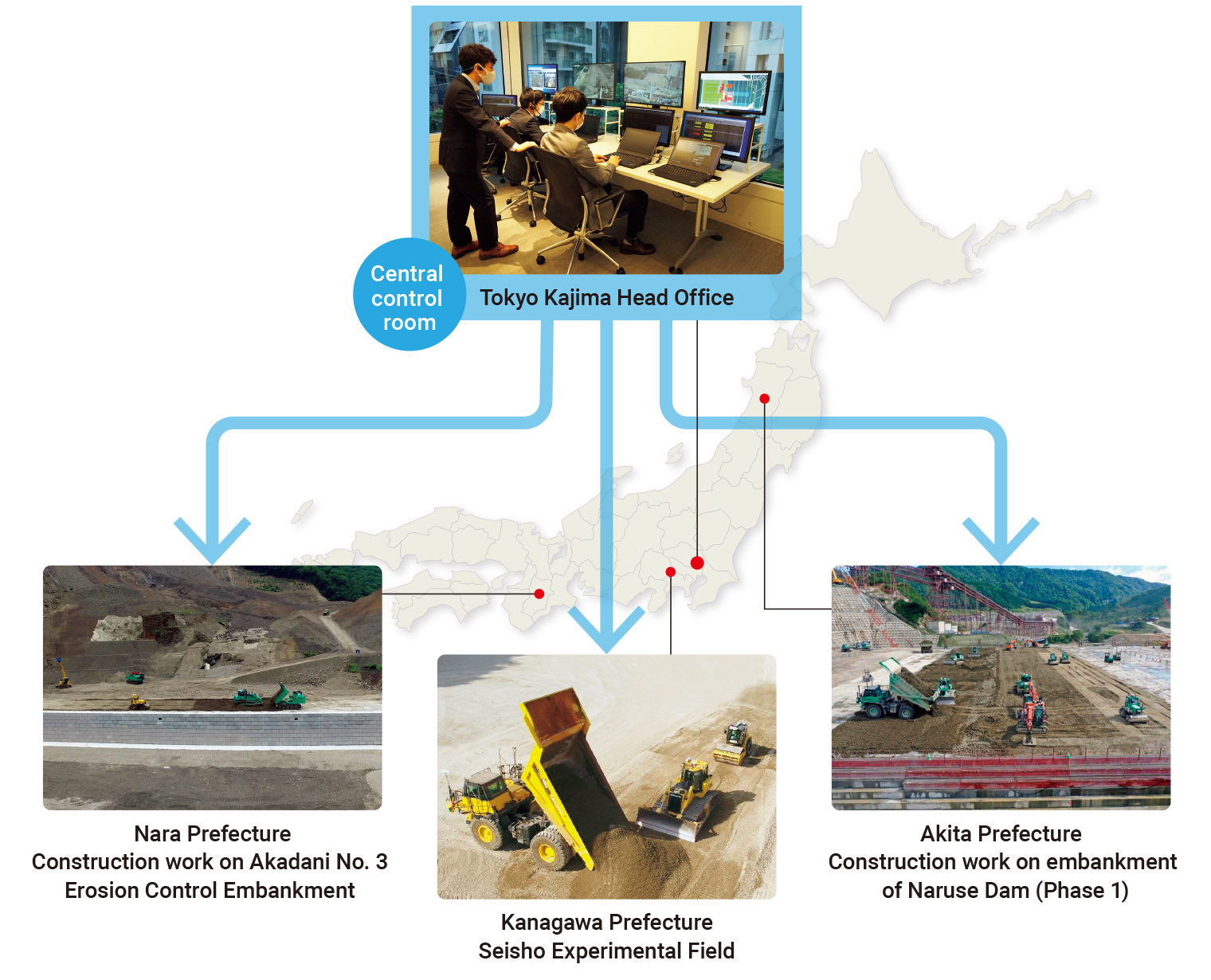

ColumnControlling—from Tokyo—

automated construction machinery operating at construction sites

around the world and, in the future, on the moon.

In October 2021, automated construction machinery operating at three construction sites nationwide where A4CSEL is installed was successfully controlled centrally from a control room set up at the head office in Minato ward, Tokyo. A total of twenty pieces of automated construction machinery were installed at three sites (namely, Naruse Dam in Akita Prefecture, disaster restoration work at the Akadani No. 3 erosion-control embankment in Wakayama Prefecture, and the Seisho Experimental Field in Kanagawa Prefecture) and remotely operated by only four A4CSEL operators (named “IT pilots”).

In the near future, it may be possible to (i) control automated construction machinery operating at sites throughout Japan from home via “telework” or (ii) operate automated construction machinery not only in Japan but also around the world, or even on the moon, with a single click from Tokyo.