Pick Up Technologies

Total concrete volume acceptance management system using video analysis

Concrete and

Construction Materials Group

Construction management automation technology useful for ensuring quality

The total concrete volume acceptance management system using video analysis obtains the gradient of concrete that flows through the chute of agitator truck through video analysis and estimates slumps based on new criterion calculated from the gradient in real-time to automatically eliminate concrete with low workability, so-called rigid concrete.

Usually, the concrete acceptance inspection is a sampling inspection as often as once every 20 to 150 m3 segments. Therefore, rigid concrete with small slump may be overlooked if these are not subject to inspection. If such concrete is casted, it causes problems such as clogging of piping or filling failures, resulting in significant degradation of structural quality.

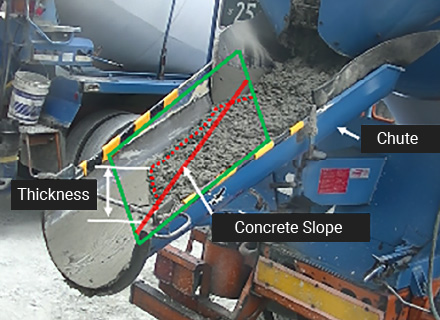

Therefore, we started the development of this system by automatically identifying rigid concrete with small slump. First, we visualized the movement of concrete going down through the chute based on which experienced engineers precisely estimate slumps by using an eye tracking device that captures the movement of human eyeballs and calculates their observations. The results revealed that these engineers estimate the rigidity of concrete based on the gradient of concrete flowing through the chute, and that more rigid concrete is thick and flows down slowly. Based on these facts, we invented a method to identify this characteristic through video analysis.

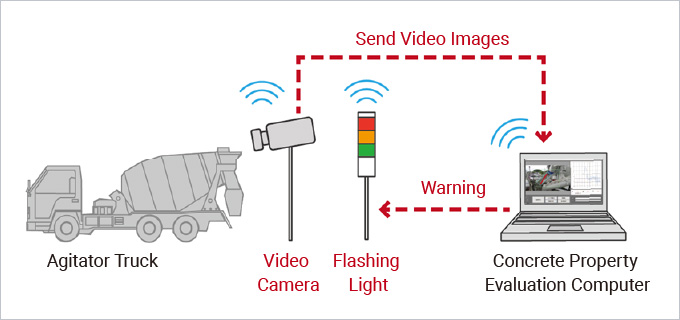

This system consists of a video camera, a PC to determine material properties, and a rotary beacon light. This system allows acceptance management and inspection of the total concrete volume delivered without having to allocate monitoring staff on site. In addition, this system can transfer video data to manage monitoring in the office or to conduct concrete acceptance inspections from remote locations. The system can also save manpower while ensuring structural quality.

Kajima is dedicated to analyzing data obtained using ICT and sensing technology that replaces the five senses of experienced engineers who reliably manage construction and to applying analysis results to the PDCA cycle of construction management to improve productivity through labor and manpower saving while maintaining quality.

Important Facts

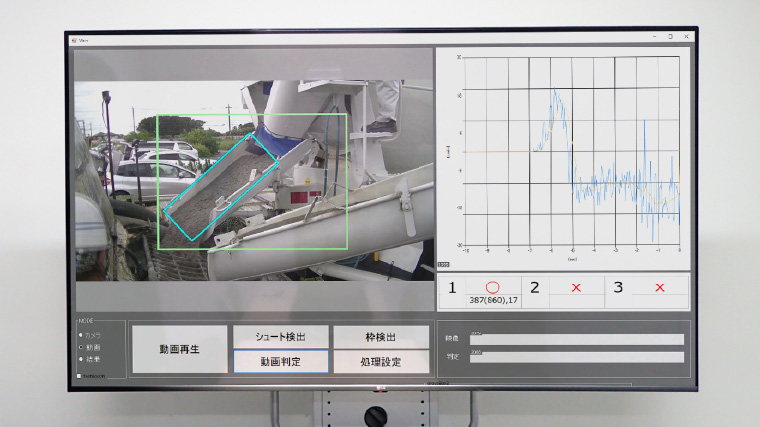

This system consists of a commercially available video camera for filming, a rotary beacon light to issue alerts, and a PC that incorporates an analysis system (left figure). When the video camera captures the chute of the agitator truck, AI automatically recognizes the position of the chute and the evaluation range (green frame in the right figure). After unloading starts, the system detects rigid concrete based on how concrete flows down through the chute and issues alerts with the rotary beacon light.

Configuration of this system

This system consists of a commercially available video camera to monitor concrete flow along the chute of the agitator truck, a rotary beacon light to issue alerts, and a PC equipped with an analysis system.

Evaluation criterion in this system

AI automatically recognizes the position of the chute of the agitator truck and the evaluation range (green frame) from video image. After unloading starts, AI evaluates the characteristics of the rigid concrete based on the gradient of concrete through video analysis and estimates slump of the concrete.

Expected Application Fields

- All fields where concrete structures are constructed